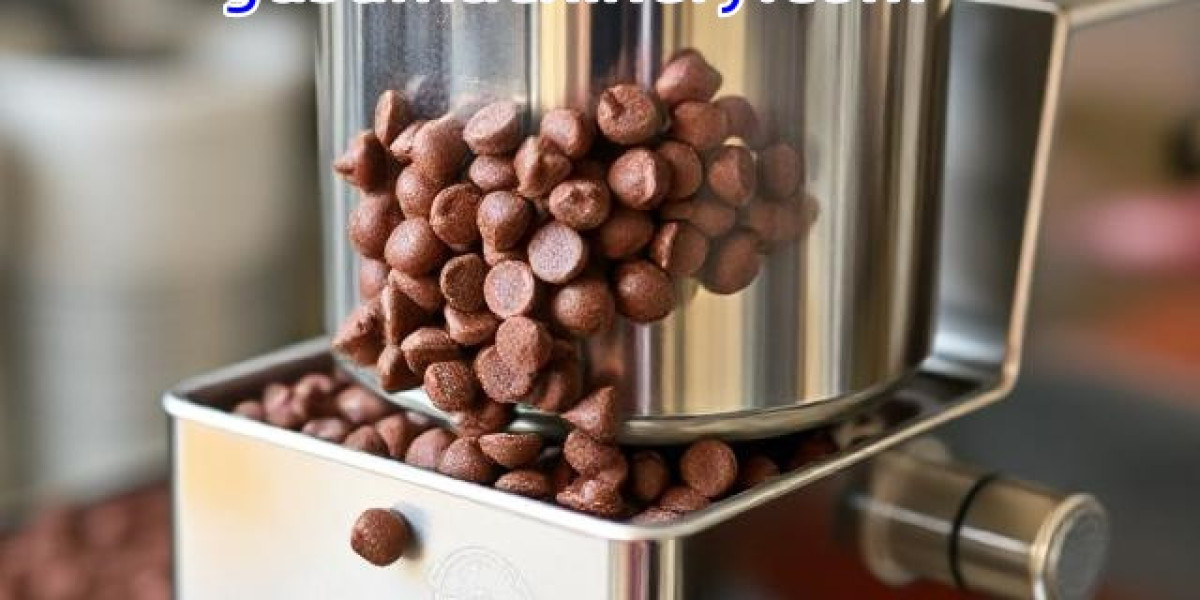

Chocolate Ball Mill plays an important role in improving production efficiency for chocolate manufacturers seeking smooth workflow and consistent refining results. Many facilities rely on this equipment to achieve stable particle size, even texture, and controlled processing conditions. Its continuous motion and structured grinding process help businesses maintain steady output while reducing the need for intensive manual handling.

Modern chocolate production requires a balance between efficiency and product consistency. Facilities often face challenges such as uneven refining, time-consuming manual mixing, and the need to maintain stable quality across different batches. Equipment designed for controlled grinding and mixing helps address these concerns by streamlining the entire refining stage. With stable operation, manufacturers can manage their production schedules more effectively without sacrificing texture or flavor standards.

Another advantage of this type of equipment is its ability to handle different formulation requirements. As consumer demand grows for varied chocolate products, manufacturers must adjust recipes while maintaining reliable performance. A machine built to support different viscosities and ingredient combinations gives businesses the flexibility to produce multiple product lines without extensive downtime for adjustments. This adaptability helps facilities expand offerings while keeping production efficient.

Energy management is also an essential element in modern manufacturing. Machinery with stable operation and optimized motion supports cost-effective production cycles. By maintaining consistent refining speed and grinding performance, facilities can reduce waste and minimize reprocessing needs. This contributes to smoother overall workflow and better use of operational resources.

Daily operation becomes more manageable when equipment is designed for simplified cleaning and routine checks. A machine that offers easy-access components and smooth interior surfaces supports hygiene standards and shortens downtime. Operators benefit from a predictable, user-friendly routine that keeps production moving while reducing unnecessary interruptions.

Gusumachinery provides equipment designed with these considerations in mind. Their systems support stable refining performance, dependable grinding action, and workflow-oriented design features that help facilities maintain consistent output. Businesses also appreciate the durable construction and straightforward operation that integrates well with daily production requirements. By incorporating such machinery into their processes, manufacturers can strengthen their production capabilities while maintaining reliable chocolate quality.

In addition, scalable performance is important for growing businesses. As production demand increases, machinery that accommodates higher throughput without requiring major structural changes allows manufacturers to expand gradually and sustainably. With dependable grinding action and consistent mixing, this type of equipment supports long-term operational planning and product development.

In conclusion, facilities aiming to enhance production efficiency can benefit from equipment that offers dependable refining performance, adaptable functionality, and workflow-friendly operation. Solutions from Gusumachinery support these goals, helping businesses maintain steady output and consistent quality throughout the production cycle. More insight into this type of equipment can be viewed at https://www.gusumachinery.com/news/industry-news/what-is-a-chocolate-ball-mill-everything-you-need-to-know.html