The Multi-Tasking Machine Tools Market is witnessing significant growth driven by advancements in manufacturing technologies and the increasing demand for efficiency in production processes. These tools combine multiple machining operations into a single setup, reducing production time and enhancing precision. As industries strive for cost-effective and versatile manufacturing solutions, the market for multi-tasking machine tools is expanding. Innovations in automation and smart manufacturing are further propelling this growth, making it essential for manufacturers to invest in advanced multi-tasking systems to remain competitive in the evolving landscape.

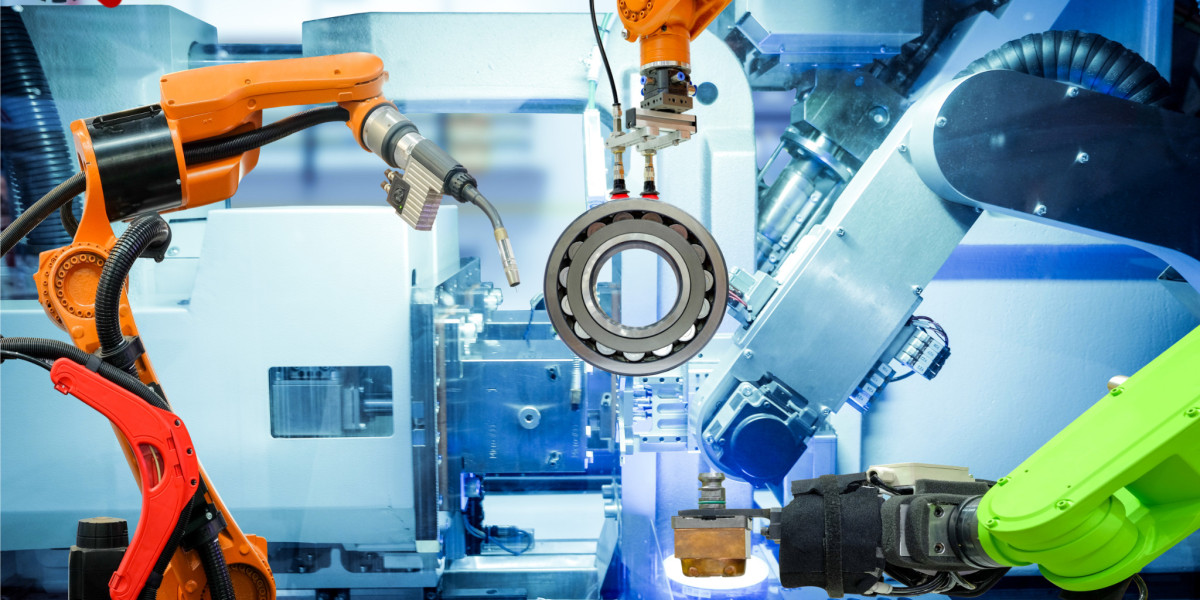

The Multi-Tasking Machine Tools Market is transforming the modern manufacturing landscape by combining multiple machining capabilities into one system. These advanced machines, capable of performing turning, milling, drilling, and tapping in a single setup, are revolutionizing productivity and precision across industries. As the global demand for complex components and reduced production times increases, manufacturers are turning to multi-tasking machine tools for greater efficiency and operational flexibility. This market’s growth is being driven by technological advancements, automation, and the shift toward smart manufacturing systems.

Market Overview

Multi-tasking machine tools are becoming indispensable in industries such as aerospace, automotive, energy, and general engineering. These machines significantly minimize setup time, reduce human error, and optimize space utilization. The market is expected to witness substantial growth as more manufacturers adopt automation and Industry 4.0 solutions. Companies are integrating real-time monitoring, IoT-enabled diagnostics, and AI-driven predictive maintenance to enhance overall equipment effectiveness. The combination of precision, versatility, and automation has made these machines the cornerstone of next-generation production systems.

Technological Advancements Fueling Growth

Technology has played a pivotal role in shaping the multi-tasking machine tools industry. The integration of Computer Numerical Control (CNC) technology has revolutionized machining accuracy and process repeatability. Furthermore, hybrid machining—combining additive manufacturing and subtractive processes—has opened new opportunities for complex part production. Tooling innovations, real-time tool wear analysis, and adaptive control systems are enhancing reliability and performance. These developments are enabling manufacturers to produce high-quality components with tighter tolerances and reduced waste, contributing to sustainability goals.

Industry Applications

The aerospace and defense sector remains one of the largest adopters of multi-tasking machine tools due to their ability to produce intricate components like turbine blades and engine parts with high precision. In the automotive industry, the demand for lightweight and complex designs is increasing the reliance on advanced machining solutions. Similarly, the energy sector, especially in oil, gas, and renewable energy equipment manufacturing, benefits from the flexibility of multi-tasking machines to produce high-strength components efficiently. The medical device industry is also increasingly adopting these tools for producing implants and surgical instruments with stringent accuracy requirements.

Market Drivers

Several factors are driving the market’s rapid growth. Firstly, the need to reduce operational costs while maintaining production quality is pushing manufacturers toward integrated machine systems. Secondly, the global labor shortage in skilled machining operators is encouraging companies to invest in automated solutions. Thirdly, increasing demand for customized components and short production runs requires machines that can adapt quickly to new designs. Additionally, sustainability initiatives are motivating industries to adopt technologies that minimize material waste and energy consumption, areas where multi-tasking tools excel.

Regional Insights

North America and Europe have traditionally led in the adoption of advanced machining technologies due to their strong manufacturing base and technological expertise. However, the Asia-Pacific region is rapidly catching up, driven by the expansion of the automotive, electronics, and aerospace sectors in countries like China, Japan, and India. Governments in these regions are supporting industrial modernization programs to enhance competitiveness. Latin America and the Middle East are also emerging as promising markets as manufacturers invest in upgrading their facilities with high-performance machine tools.

Competitive Landscape

The market features several leading players focusing on innovation, strategic partnerships, and expansion of product portfolios. Key manufacturers are investing in R&D to develop machines with better energy efficiency, improved control systems, and higher throughput. Companies are also adopting digital platforms to offer remote monitoring and predictive maintenance services. The emphasis on after-sales support and training programs has become a vital strategy for gaining customer loyalty. Mergers and acquisitions are further shaping the competitive dynamics, with larger firms acquiring smaller specialized manufacturers to strengthen their technological capabilities.

Future Trends

The future of the multi-tasking machine tools market lies in complete automation and digitalization. The incorporation of AI, machine learning, and data analytics will allow for self-optimizing production systems capable of real-time adjustments. The trend toward miniaturization and lightweight materials will continue to push the boundaries of machine precision. Moreover, with sustainability becoming central to manufacturing strategies, eco-friendly and energy-efficient machining systems are expected to dominate future product development. Cloud-based monitoring, virtual prototyping, and digital twins will further transform the operational landscape.

Conclusion

The Multi-Tasking Machine Tools Market is at the forefront of industrial transformation. As manufacturers continue to seek cost-effective, precise, and flexible machining solutions, the demand for these advanced tools will only intensify. Their ability to combine multiple operations within a single setup not only improves efficiency but also ensures superior product quality. With continued technological advancements and growing industrial automation, this market promises robust growth in the coming years.

FAQs

1. What are multi-tasking machine tools?

Multi-tasking machine tools combine multiple machining functions like milling, turning, and drilling into one machine for greater efficiency and accuracy.

2. Which industries primarily use multi-tasking machines?

Industries such as aerospace, automotive, energy, and medical equipment manufacturing are the main users of these advanced machines.

3. What factors are driving the market growth?

The key drivers include demand for automation, cost reduction, precision manufacturing, and sustainability initiatives.

More Related Reports:

Robotic Lawn Mower Market Growth

Trunnion and Floating Ball Valves Market Growth