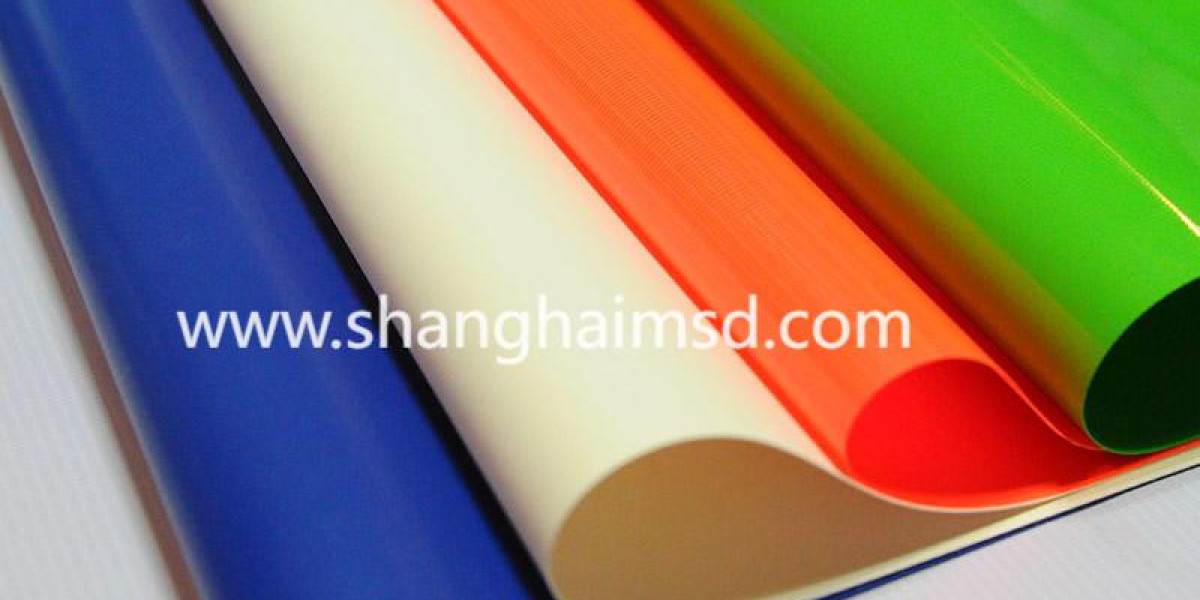

Understanding the evolution of industrial textile materials begins with examining how PVC Tarpaulin Fabric has become a core component in heavy-duty protection systems used worldwide. Positioned between traditional canvas and high-tech polymer membranes, this engineered composite offers a blend of durability, waterproof performance, and design flexibility. Shanghai MSD International Trade Company has contributed to the development, manufacturing, and global distribution of advanced PVC-coated textiles that meet stringent industry demands for reliability and consistency.

At its foundation, modern PVC tarpaulin is built on a high-tenacity polyester woven base. This internal scrim—typically made through 500D, 1000D, or 1500D yarn constructions—provides the fabric with its mechanical strength. The coating process then embeds flexible polyvinyl chloride onto the polyester, creating a robust composite capable of withstanding tension, tear forces, and exposure to severe outdoor environments. To improve adhesion and longevity, the yarns are often pre-treated with bonding agents that allow the PVC layer to integrate deep into the fiber structure.

The production of high-performance PVC tarpaulin involves a series of controlled processes such as knife-over-roll coating, spread coating, or calender lamination. Knife-over-roll coating ensures uniform thickness and strong fusion between the layers, while calendering enables production of wide-format sheets with smooth surfaces and lower porosity. During manufacturing, additives such as UV stabilizers, mildew inhibitors, fire-retardant compounds, and plasticizers are introduced to customize the material for different environmental and mechanical requirements. Shanghai MSD works with specialized coating facilities that apply multi-layer techniques to ensure dimensional stability and superior surface resilience over prolonged use.

Key performance metrics determine whether a tarpaulin meets global industrial standards. Tensile strength and tear resistance are measured according to ISO 1421 and ISO 4674, ensuring the fabric can withstand repeated stress without deformation. Waterproof performance, evaluated by hydrostatic pressure testing, confirms that the coated surface remains completely impermeable even under heavy rainfall or water pooling. Flame retardancy, particularly for tent structures and logistics covers, follows international standards such as NFPA 701 or B1/M2 classifications. Abrasion resistance testing further validates the product’s suitability for long-term industrial deployment, especially in transportation, agriculture, and construction.

Thermal stability is another essential factor. PVC tarpaulin must retain flexibility in cold conditions while resisting brittleness and cracking. Plasticizer formulations and polymer blending play critical roles in achieving this balance. High-quality coated fabrics maintain elasticity even at temperatures down to –20°C, making them suitable for cold-chain logistics and outdoor winter installations. Shanghai MSD enhances these material characteristics through extensive QA monitoring and batch-level inspection, ensuring that each production run meets strict consistency requirements.

The applications of PVC-coated tarpaulin continue to expand across industries. In logistics and transportation, truck side curtains and cargo covers rely on the fabric’s excellent weatherproof properties. In agriculture, the material is commonly used for greenhouse roofing, grain storage coverings, and irrigation pool liners due to its resistance to moisture and microbial growth. Emergency shelters and relief tents benefit from the fabric’s flame retardancy and strength-to-weight ratio. Meanwhile, large-scale advertising banners, event canopies, and inflatable structures utilize the material’s printability and dimensional stability. Shanghai MSD provides customized specifications tailored for these diverse sectors, allowing clients to select weight, coating thickness, surface finish, and reinforcement options according to their exact operational needs.

As global requirements for environmental responsibility increase, PVC tarpaulin manufacturing has also moved toward greener formulations. Heavy-metal-free stabilizers, low-VOC plasticizers, and recyclable polymer blends help reduce the ecological impact without compromising performance. Research is ongoing to develop alternative coating chemistries and hybrid composites that deliver improved sustainability in large-scale outdoor applications. Shanghai MSD continues to collaborate with material scientists and production partners to push advancements in long-life, low-emission coated textiles.For more technical insights into the composition, coating processes, and extended application range of PVC tarpaulin, you may visit Shanghai MSD’s resource page:

https://www.shanghaimsd.com/news/what-is-pvc-tarpaulin-fabric.html