Modern industrial systems thrive on orchestrated timing – where motors, valves, and processes activate in precise sequences that maximize efficiency while preventing mechanical conflicts. Achieving this synchronized dance demands components capable of interpreting complex operational rhythms and translating them into flawless execution. A specialized Multifunction Time Relay Manufacturer serves as the essential composer in this industrial symphony, engineering devices that transform abstract timing requirements into tangible, reliable machine behaviors. These unassuming units become the silent conductors ensuring systems perform with fluid grace rather than disruptive clatter.

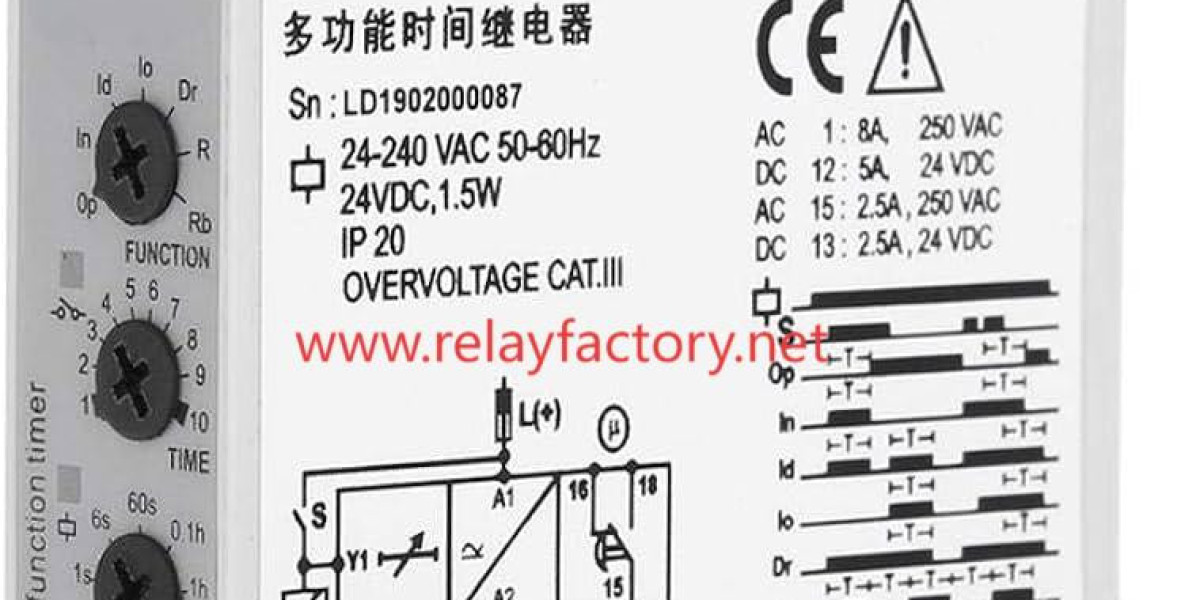

Programming versatility forms the core intelligence. Advanced units allow engineers to configure intricate delay patterns, cyclical operations, and conditional triggers through intuitive interfaces. This flexibility replaces entire racks of single-function timers with one intelligent device capable of managing multiple interdependent sequences. The ability to store diverse timing profiles enables rapid changeovers between production runs, minimizing downtime when manufacturing different products. This adaptability stems from sophisticated firmware developed through deep understanding of real-world industrial timing challenges beyond theoretical specifications.

Environmental resilience ensures unwavering performance. Components must maintain timing accuracy despite electromagnetic interference from heavy machinery, temperature fluctuations near ovens or freezers, and constant vibration in manufacturing environments. Premium construction involves encapsulated circuit boards, secure terminal designs resistant to loosening, and coatings that prevent corrosion in humid conditions. This rugged reliability allows installations in control panels adjacent to production lines rather than requiring isolated electrical rooms, simplifying maintenance and reducing installation costs.

Integration intelligence facilitates seamless communication. Contemporary timing devices often feature status feedback contacts that relay operational data to supervisory systems, enabling predictive maintenance alerts before failures occur. Compatibility with various control voltages allows deployment across legacy and modern equipment without additional converters. This connectivity transforms timers from isolated components into integrated system participants that contribute valuable operational insights.

Relayfactory specializes in creating these industrial harmonizers. Our expertise as a premier Multifunction Time Relay Manufacturer focuses on devices known for their programming depth, environmental toughness, and seamless integration capabilities. We engineer solutions that precisely orchestrate your operational sequences, preventing equipment conflicts while optimizing production flow. Trust Relayfactory for timing intelligence that transforms mechanical processes into synchronized performances – where every activation occurs with purpose, coordination, and reliability that protects your valuable assets.Click https://www.relayfactory.net/product/ to reading more information.