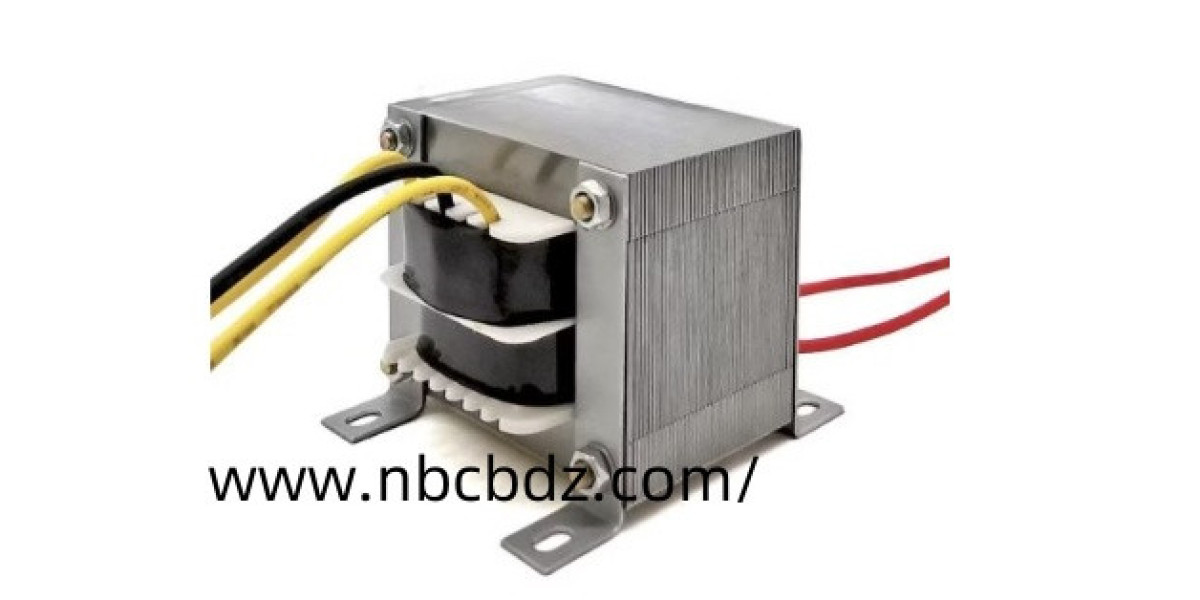

The manufacturing approach behind an EI Transformer Factory and the product philosophy of Nbcbdz intersect in ways that influence how engineers, integrators, and system designers evaluate power-conversion components. In practice, the value lies not in dramatic claims but in careful alignment between structure, material handling, winding precision, and long-term usability. When these elements work together with clarity, project teams gain predictable performance characteristics that assist in system planning and risk management.

A well-structured transformer workflow begins with core preparation. The attention placed on lamination consistency, joint fit, and magnetization behavior shapes how a device responds under shifting loads. Engineers often focus on steady flux distribution and controlled heat levels because small deviations can shift energy use or durability trajectories over time. By treating these aspects as foundational, manufacturers help users anticipate behavior across various installation settings, whether compact enclosures or broader equipment assemblies.

Coil winding follows as a crucial stage. Its significance extends beyond the visual symmetry of arranged turns; it influences impedance, vibration tendencies, and acoustic patterns. Many teams appreciate when windings maintain predictable tension and spacing, as this supports controlled electrical response. In practical applications—from industrial units to specialized electronic platforms—such stability can simplify troubleshooting and future upgrades. Careful coil management also complements the insulation strategy, which must balance thickness, elasticity, and thermal response.

Insulation layers often determine how equipment responds to environmental factors. Engineers tend to evaluate how these materials behave when humidity rises, when airflow changes, or when voltage conditions fluctuate. A consistent insulation process allows them to forecast operational margins without relying on assumptions. This reliability also aids in resource planning for maintenance cycles.

Terminals and connection points finalize the assembly. Their placement and material choices influence how easily integrators can route wiring, redesign internal layouts, or add protective circuits. Thoughtful positioning supports a clean interface with auxiliary modules, reducing the probability of assembly-stage mistakes. When these features align with clearly documented guidelines, product teams can accelerate certification steps and shorten integration windows.

Testing and verification conclude the production sequence. Functional checks, coil resistance measurements, insulation evaluations, and load simulations help ensure equipment behaves within expected parameters. Though each project differs, this methodical approach provides engineers with predictable reference points. It does not promise extremes; instead, it provides a structured path for assessing suitability.

As industrial requirements shift, consistent processes become increasingly valuable. They allow designers to focus on refinement rather than uncertainty. By treating transformer construction as an evolving craft supported by steady methodology, teams maintain room for adaptation without abandoning reliability. This balance often appeals to project planners looking for components that integrate smoothly into broader system goals.

If you prefer to evaluate sample specifications or examine application notes, the next step is straightforward. Let your curiosity guide you through a detailed walk around the digital workshop at https://www.nbcbdz.com/product/ , where each click opens another layer of insight for your technical planning.