In today’s competitive packaging landscape, manufacturers must prioritize both productivity and cost efficiency, and the Cap Compression Molding Machine has emerged as a critical tool for achieving these objectives. Taizhou Chuangzhen Machinery Manufacturing has engineered advanced systems that combine precision molding, reduced energy usage, and reliable performance, enabling factories to meet growing market demand while maintaining operational flexibility.

Consumer expectations have shifted toward closures that not only provide secure sealing but also demonstrate consistent quality and aesthetic appeal. Beverage companies, pharmaceutical manufacturers, and personal care producers increasingly require high-precision caps capable of withstanding varying transport and storage conditions. Compression molding technology addresses these needs by producing caps with uniform wall thickness, controlled weight, and consistent torque properties. This level of precision helps brands maintain product integrity and reduce complaints or returns.

Energy efficiency has become a major driver for production upgrades. Rising electricity costs and stricter environmental regulations push manufacturers to adopt machinery that minimizes power consumption while sustaining high throughput. Advanced compression systems employ servo-driven mechanisms, efficient hydraulic circuits, and optimized thermal management to reduce energy demand. Taizhou Chuangzhen Machinery Manufacturing has refined these features, providing machines that consume less electricity without compromising speed or quality, supporting sustainable production practices in multiple sectors.

Another advantage lies in material optimization. Compression molding requires only the polymer necessary for each cavity, significantly reducing scrap and flash compared with other molding methods. By integrating improved cooling designs and precise mold geometries, manufacturers can produce lightweight, strong, and reliable caps while reducing material costs. For high-volume production lines, this translates into substantial savings and supports eco-friendly initiatives, a growing priority for both domestic and international markets.

Versatility in application is another hallmark of modern compression systems. Beverage bottling plants, chemical packaging facilities, and medical product lines all benefit from the technology’s ability to maintain consistent quality across a variety of cap styles, including standard screw tops, flip-tops, and specialized dispensing closures. Uniform cavity pressure and temperature distribution result in closures with precise dimensions, ensuring compatibility with downstream capping and filling equipment while reducing rework or rejects.

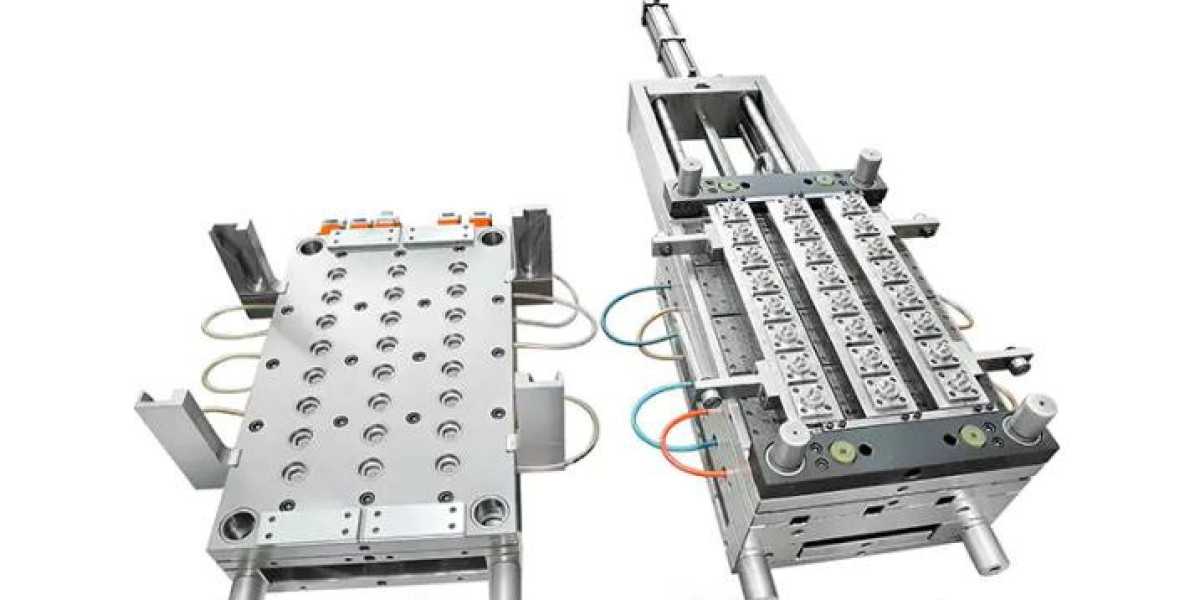

Operational performance is further enhanced through automation and intelligent monitoring. Modern systems include digital sensors to track pressure, cycle time, and temperature in real time, allowing operators to adjust processes immediately when deviations occur. Reduced manual intervention, coupled with modular designs for mold upgrades and feeding systems, ensures minimal downtime and extends machine life. Taizhou Chuangzhen Machinery Manufacturing incorporates these innovations to increase reliability and maintain consistent output under demanding production schedules.

Technological advancements also enable manufacturers to tackle complex closure designs. Enhanced mold steels, refined runner systems, and precise thermal controls improve surface finish and mechanical strength, allowing more intricate shapes while maintaining structural integrity. Predictive monitoring and data-driven maintenance features further improve production reliability, ensuring that high-volume operations remain efficient and cost-effective.

For manufacturers seeking high-quality, energy-efficient, and versatile cap production equipment, Taizhou Chuangzhen Machinery Manufacturing offers solutions designed to meet evolving industry needs. Their advanced compression systems combine precision, durability, and operational efficiency, supporting diverse packaging scenarios while minimizing material and energy waste. Detailed product information and specifications are available at: https://www.capping-machine.net/product .