Introduction

You just invested in a Brother PR-series machine—the PR670E, PR1055X, or the latest beast—and you’re ready to stitch logos that fly off the shelf. You load your client’s JPG or PNG, hit start, and… thread breaks, camera errors, and stitches that look like they partied too hard. The issue isn’t your $15k machine; it’s the file format. PXF is the native language of every PR machine, packed with camera data, auto-trims, and color sorting that make it run at full speed. Feed it a generic DST or PES and you lose all that magic. The good news? Turning any JPG or PNG into a production-ready PXF is straightforward once you know the steps. Here’s your no-drama guide to how to convert image to PXF file and keep your ten-needle humming without a single hiccup.

Why PXF Is the Only Format Your PR Truly Loves

PXF isn’t just another extension—it’s Brother’s high-performance blueprint. It tells your machine exactly where the camera should look, when to trim, and how to sort colors for minimal thread changes. A lazy conversion loses those smarts. A pro PXF lets your PR hit 1,000 stitches per minute with zero long jumps or birdnests.

Start with the Cleanest Image Possible

Garbage in, garbage out. Pros demand vector files (AI, EPS, SVG) because they scale forever. No vector? Use the highest-resolution JPG or PNG you can find—300 DPI minimum with strong contrast. Open it in free Inkscape or Illustrator, delete the background (remove.bg does this in one click), and crop tight. Merge overlapping shapes and delete stray pixels. Five minutes of cleanup saves five hours of stitch headaches.

Simplify Colors and Details

Your PR has ten needles, not fifty. Reduce colors to eight max (six is better). Merge tiny details that vanish at stitch size. Boost contrast so edges stay razor-sharp. Think bold and clean—your design should read perfectly at 2.5 inches on a cap front.

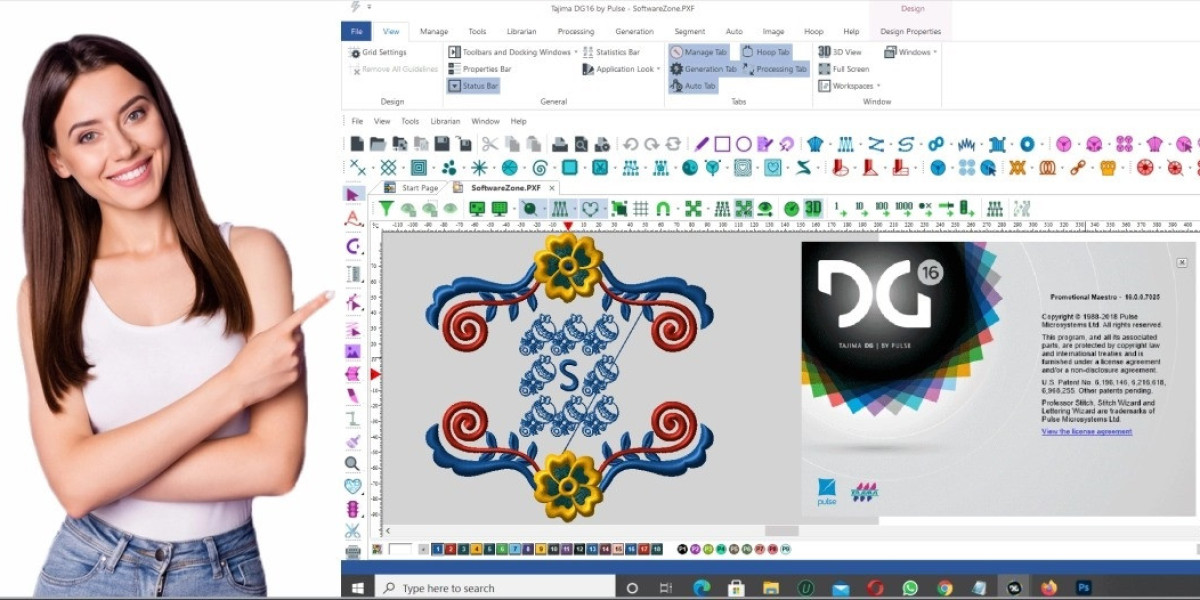

Choose Your Conversion Tool

Hatch by Wilcom with the Brother PR module is the gold standard—true PXF export with camera data and auto-optimization. Tajima Pulse does it too (pricey but flawless). Embrilliance Enthusiast + the PR add-on gets you 95 % there for under $600. Ink/Stitch can export PXF free if you’re patient with settings. Pick your budget and never look back.

The 8-Step Pro Workflow

Pros follow this exact sequence every time. Clean paths and remove hidden junk. Lay medium-density tatami underlay at 90° to final fill direction. Add edge-run under satin columns. Use tatami fill with 4.2 mm spacing for large areas. Convert every jump over 7 mm to a travel run. Add 12–18 % pull compensation for knits. Include 2", 3.5", and 10" versions in one file. Export genuine PXF with all the Brother goodies.

Get Instant Feedback with 3D Previews

Top tools send a spinning 3D preview you can open on your phone. Rotate it, zoom in, check trims. See a pucker? They fix it in minutes. Approve with one tap and the final PXF lands while your coffee is still hot.

Test Stitch on the Exact Fabric

Hoop scrap twill or the cap you’ll use in production. Run 100 stitches. Check registration with the laser, tension (top thread 2/3 visible on back), and overall pop. One 90-second test saves a mountain of blanks.

Emergency Rush Options

Need 800 caps by Friday? Pros live for this. Upload your JPG or PNG in the morning, pay a small rush fee, and get the PXF plus thread chart before lunch. One shop turned around 1,200 pieces for a tournament in under four hours using this exact process.

Creative Projects PR Owners Love

Add 3 mm puff under crowns for streetwear fire. Stitch tone-on-tone luxury on performance polos. Drop individual names in one hooping with IQ Designer. Metallic outlines that catch stadium lights. One perfect PXF unlocks them all.

Common Mistakes That Kill PR Runs

Renaming DST to PXF (it’s not the same). Skipping underlay on performance polos (shrinkage city). Using 47 colors (your ten-needle cries). Running full speed on puff (foam explodes). One test cap catches every sin.

The Future Is Already Here

Brother keeps adding PXF-only features—auto-tension, wireless hoops, cloud stitching. A file built with these best practices today will run perfectly on machines released in 2030.

Conclusion

Converting JPG and PNG images to flawless PXF files is now a repeatable, 20-minute process: clean the art, simplify, underlay smart, test once, and watch your PR machine hit 1,000 SPM like it was born to. No drama, no wasted blanks—just stitches that make clients fight over your samples.

Grab your next image tonight, run these steps, and stitch your first perfect cap by morning. Your Brother PR is starving for real PXF—feed it right and listen to it roar.