Introduction

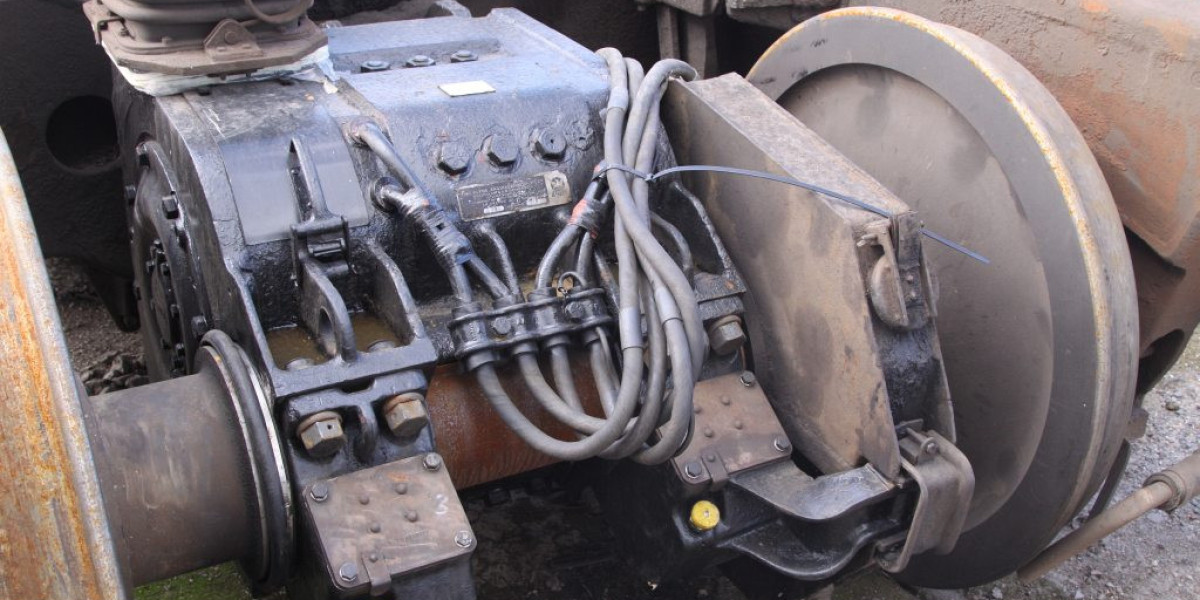

The Railway Traction Motor Market is a core segment of the railway propulsion and rolling stock industry, supplying electric motors that convert electrical energy into mechanical power to drive trains. Traction motors are installed in locomotives, electric multiple units, diesel-electric trains, metros, trams, and high-speed rail systems. They directly influence acceleration, hauling capacity, energy efficiency, noise levels, and overall reliability of rail vehicles. As rail transport expands as a sustainable mobility solution and electrification accelerates across passenger and freight networks, traction motors are becoming increasingly critical to achieving high performance, lower emissions, and reduced lifecycle costs.

Market Drivers

One of the primary drivers of the Railway Traction Motor Market is the global push toward railway electrification. Governments are investing heavily in electrified rail corridors to reduce dependence on diesel fuel, lower operating costs, and cut carbon emissions. Electrification projects directly increase demand for electric locomotives and multiple units, driving strong demand for high-efficiency traction motors.

Urbanization and metro rail expansion are another major growth driver. Rapid population growth in urban areas is increasing demand for mass transit systems such as metros, light rail, and suburban rail networks. These systems require traction motors with high acceleration, frequent start-stop capability, and low maintenance, supporting sustained demand for advanced motor technologies.

Fleet modernization and replacement also contribute significantly to market growth. Many railway operators are upgrading aging rolling stock to improve energy efficiency, reliability, and passenger comfort. Replacing older DC motors with modern AC traction motors allows operators to reduce maintenance costs, improve performance, and comply with stricter energy efficiency and emission regulations.

Market Challenges

Despite strong demand, the Railway Traction Motor Market faces several challenges. High development and manufacturing costs are a key concern, as traction motors require advanced materials, precise engineering, and rigorous testing to meet safety and performance standards. These factors increase upfront costs and can impact procurement decisions, especially in cost-sensitive regions.

Thermal management and reliability also present challenges. Traction motors operate under high loads, variable speeds, and harsh environmental conditions, including vibration, dust, moisture, and temperature extremes. Ensuring long-term reliability and efficient heat dissipation is critical, particularly for high-speed and heavy-haul applications.

Standardization and compatibility issues add further complexity. Different rail networks operate under varying voltage levels, power supply systems, and technical standards. Designing traction motors that meet diverse regional requirements increases engineering complexity and limits economies of scale.

Market Opportunities

Technological innovation offers significant opportunities in the Railway Traction Motor Market. The shift from DC to AC traction motors, including induction motors and permanent magnet synchronous motors, is improving efficiency, power density, and controllability. These motors deliver better performance with lower maintenance, making them increasingly attractive for new rolling stock and retrofit projects.

Energy efficiency and regenerative braking represent another major opportunity. Modern traction motors integrated with power electronics enable regenerative braking, allowing trains to recover and reuse energy during deceleration. This capability significantly reduces energy consumption and operating costs, aligning with sustainability goals and energy efficiency mandates.

Digitalization and condition monitoring also create growth potential. Sensors embedded in traction motors can monitor temperature, vibration, and electrical parameters in real time, enabling predictive maintenance and reducing unplanned downtime. Such smart traction solutions support reliability-focused maintenance strategies and improve fleet availability.

Regional Insights

Asia-Pacific is the largest and fastest-growing region in the Railway Traction Motor Market, driven by extensive railway electrification, large-scale metro projects, and high-speed rail expansion. High rolling stock production volumes and strong domestic manufacturing capabilities support robust demand in the region.

Europe represents a mature but technologically advanced market. The region emphasizes energy efficiency, interoperability, and sustainability, driving demand for high-performance traction motors in passenger rail, metros, and cross-border freight services. Ongoing fleet upgrades and replacement programs sustain market growth.

North America shows steady demand, supported by investments in metro systems, light rail, and modernization of freight locomotives. While electrification is more limited compared to other regions, replacement and efficiency upgrades continue to support traction motor demand.

Other regions, including Latin America, the Middle East, and Africa, are gradually expanding electrified rail infrastructure and urban transit systems, contributing to long-term market growth.

Future Outlook

The Railway Traction Motor Market is expected to grow steadily as rail transport continues to expand as a low-emission and energy-efficient mobility solution. Electrification, urban transit development, and fleet modernization will remain the primary growth drivers over the coming decade.

Future developments will focus on higher power density, reduced weight, improved cooling systems, and enhanced energy efficiency. Permanent magnet motors and advanced inverter integration are expected to gain wider adoption, particularly in high-speed and metro applications.

As digital rail ecosystems evolve, traction motors will increasingly be integrated into smart rolling stock platforms that optimize energy use, maintenance, and operational performance.

Conclusion

The Railway Traction Motor Market plays a vital role in powering modern rail systems and enabling efficient, reliable, and sustainable transportation. Driven by electrification initiatives, urban transit expansion, and rolling stock modernization, the market offers strong long-term growth potential. While challenges related to cost, thermal management, and standardization persist, continuous technological innovation and digital integration are strengthening market prospects. Railway traction motors will remain at the heart of rail propulsion as global mobility systems increasingly rely on electrified and energy-efficient rail networks.