In today’s fast‑paced manufacturing world, precision, speed, and durability are essential components of any successful production process. Whether you’re producing industrial parts, custom merchandise, or intricate design pieces, investing in the right technology can dramatically improve quality and workflow. A laser marking machine delivers all those advantages and more — empowering businesses and creators alike with high‑precision marking capabilities that are versatile, efficient, and built to last.

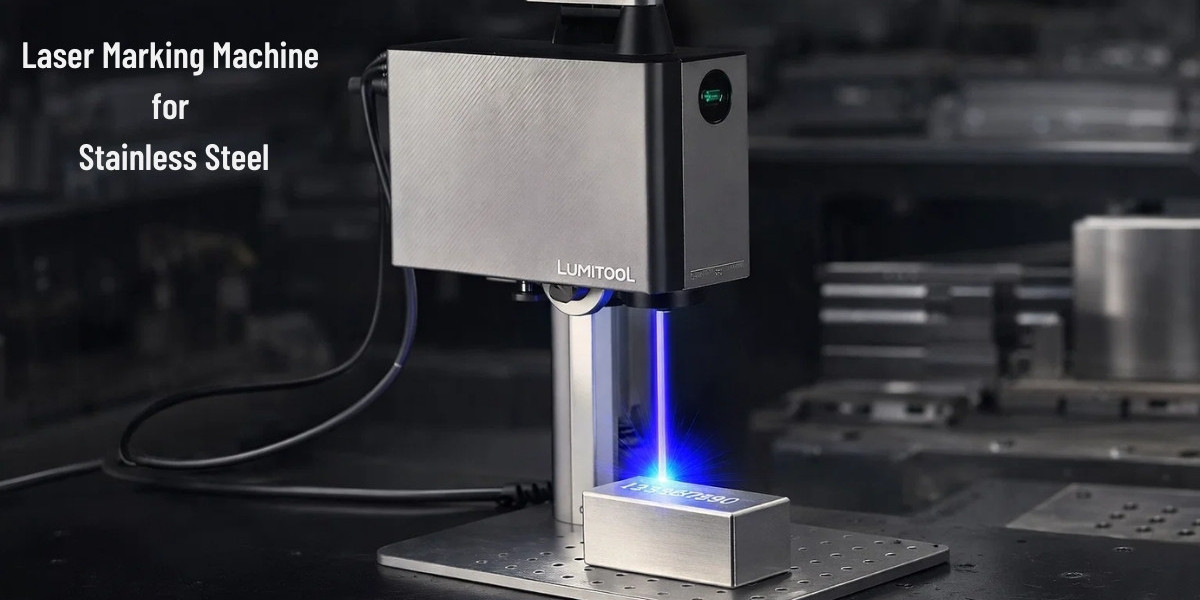

The core strength of a laser marking machine lies in its ability to produce permanent, clear, and high‑resolution marks on a wide variety of materials. Traditional marking methods such as etching or stamping often struggle to achieve consistently clean results, especially on harder surfaces. By contrast, laser marking uses concentrated light energy to interact with the surface at a microscopic level, creating precise, durable marks that withstand wear, heat, and time. This makes it ideal for industrial applications where traceability, serial numbers, logos, or barcodes must remain legible throughout the product lifecycle.

One of the most compelling benefits of modern laser marking systems is their speed and productivity. These machines operate at high marking rates without sacrificing accuracy, which means faster turnaround times and increased throughput. For manufacturers handling large batches or demanding production schedules, this speed translates directly into improved efficiency and greater output capacity. From automotive components to electronics and promotional products, the ability to mark quickly and reliably gives businesses a competitive edge.

Versatility is another major advantage. A quality laser marking machine handles a broad range of materials, including metals like aluminium, stainless steel, brass, and titanium, as well as plastics, ceramics, and coated surfaces. This flexibility allows businesses to consolidate marking tasks under a single system instead of relying on multiple specialised tools. Whether you’re customising gifts, branding industrial parts, or creating precision‑labeled components, one laser marking machine meets the needs of diverse applications without compromise.

User‑friendly design and intuitive software also enhance the value of these systems. Today’s laser machines come equipped with easy‑to‑navigate interfaces that allow operators to import graphics, adjust settings, and preview marking jobs with simplicity. This reduces training time and makes advanced marking technology accessible even to those new to laser systems. The ability to control depth, speed, and pattern directly through software gives users complete command over their output — ensuring consistent high quality from the first mark to the last.

Durability and low maintenance are hallmarks of a robust laser marking machine. With solid‑state components and no moving mechanical parts in direct contact with the material, these systems endure rigorous use with minimal wear. This results in fewer breakdowns, less downtime, and lower long‑term service costs. For businesses with continuous production demands, this reliability translates into smoother operations and a better return on investment.

Laser marking also aligns with environmentally responsible practices. Unlike methods requiring inks, chemicals, or consumable parts, laser marking produces minimal by‑products and supports cleaner workflows. This not only reduces waste but also creates a safer work environment — a key consideration for any facility focused on sustainability and operational safety.

In summary, adopting a laser marking machine offers industries a powerful combination of precision, speed, versatility, and longevity. Whether you’re a small business expanding your capabilities or an established manufacturer scaling production, this technology delivers the performance and reliability needed to meet modern marking challenges with confidence.